+86 546 6506 396

+86 546 6506 396

Auto brake has an independent R & D team

20

Research and development personnel

10

Senior technical staff

5

Expert in the industry

R hair

The company has close cooperation with world famous scientific research institutions, has advanced technology friction materials research and development center, with first-class research and development groups and sophisticated production equipment.

Reviewer

The enterprise has successfully passed TS16949 for many years.

Equipment

The factory continues to introduce advanced equipment, to solve the problem of tight capacity, to modern, mechanized production mode instead of traditional production.

Automobile brake inertia test bench

The bench test of automobile brake is to simulate the braking process of automobile. The bench test method is used to test the brake's braking efficiency, thermal stability, thermal decay, recovery, wear strength of brake lining, NVH noise test and so on. The cause of the brake noise problem is complex, its corresponding mechanism and solution of no special authority solution, braking noise is a problem of the braking system, and all parts of the brake system on May have relations, 0 to 50 hz noise, in the car is imperceptibly, 1500-15000 hz noise is very sharp, we can decide to noise, Through independent research and development of the test bench, our company has added environmental laboratory cabin, which can effectively eliminate various noise factors and have a clearer positioning of the performance of our products.

Our Equipment

Our Workshop

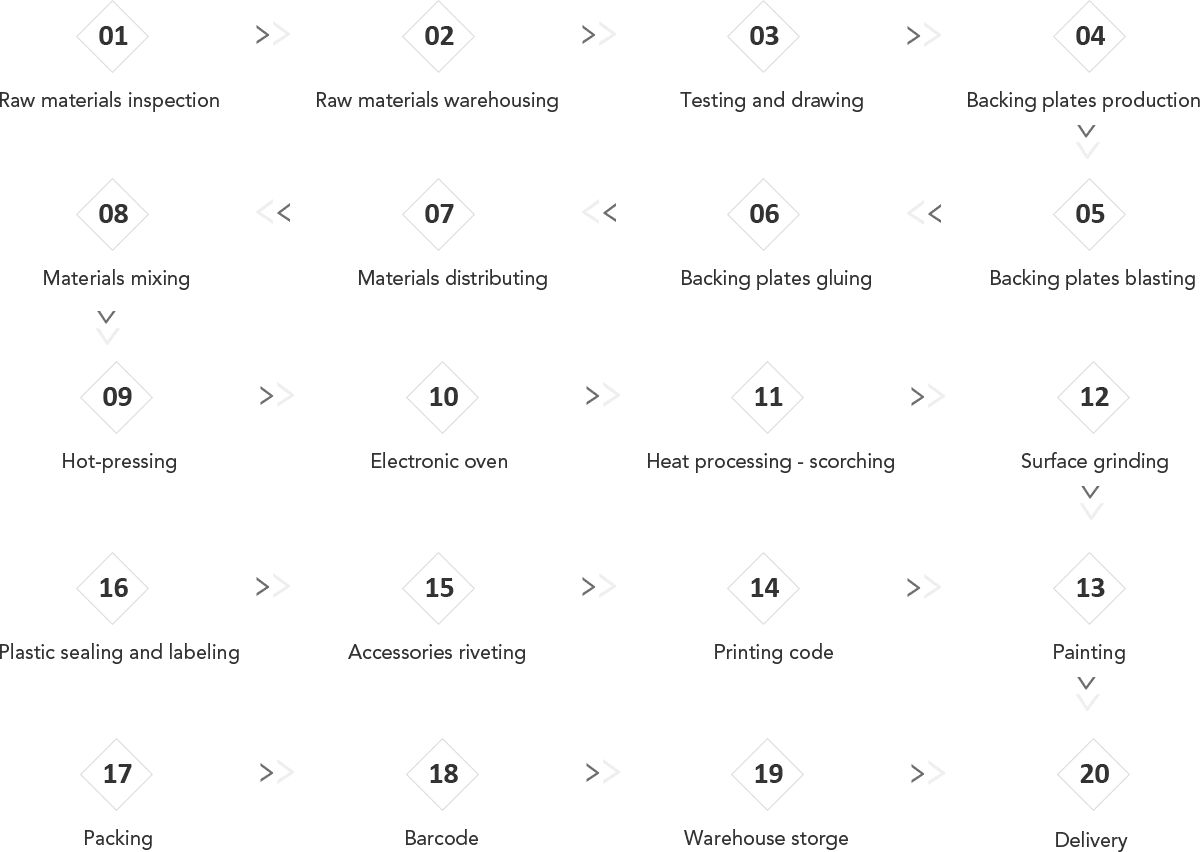

The Production Process Flow Diagram

Production Line

Our product has been a number of design patents and utility model patents, all of these are reflecting the popular R & D and supporting strength!

Navigation

Products

+86 546 6506 396

Xishui Industry, Guangrao, Dongying City, Shandong Province, China